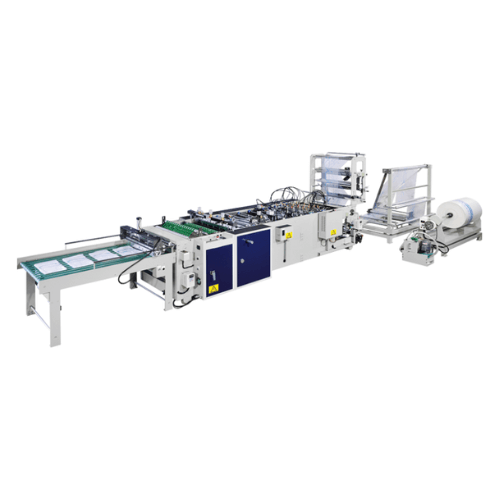

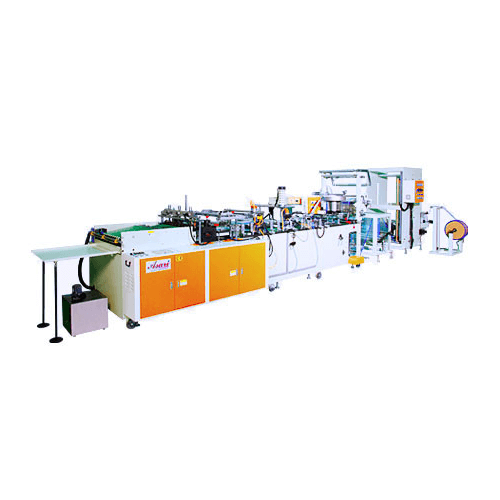

Zipper Bag Making Machine

Categories : Plastic Bag Making Machines

World Steel is a manufacturer of Zip Lock Bag Making Machines. The machines use the latest technology offering advanced performance and versatility that facilitate easy installation, setup, operation and maintenance. These machines are ideal for producing high quality ziplock bags at an excellent cost efficiency. EFFICIENT ZIP LOCK BAG MAKING MACHINE:HIGH CAPACITY AT 120 BAG/MIN The Automatic Zipper Bag Machine converts a tubular roll of pp material with clip chain structure into a side seal bag, no need to purchase additional zippers. The machine is capable of running at 120 bags / minute. This saves cost, space and labor. AUTOMATIC ZIPPER BAG MACHINE FOR PP FILM Our Automatic Zipper Bag Making Machine can be used for producing a high quality side sealed zipper bag from PP materials.

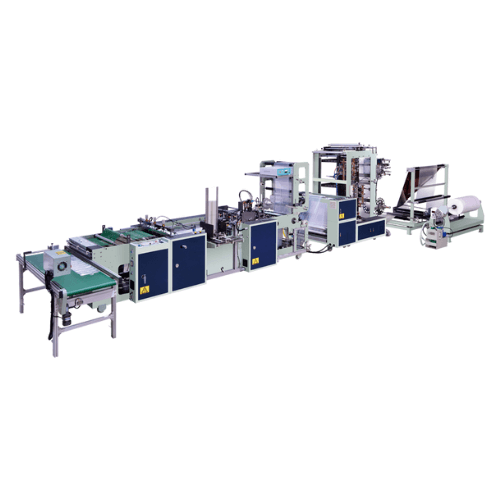

Fully Automatic High Speed 2 Lines Saddle Bag & Wicket Bag Making Machine SSD-600-L2

Categories : Plastic Bag Making Machines

Computer control over the entire process From film roll to final pruduct, one process flow Automatically stop when running out of film / film feeding blocks or jam High-productivity performace saves time and labor

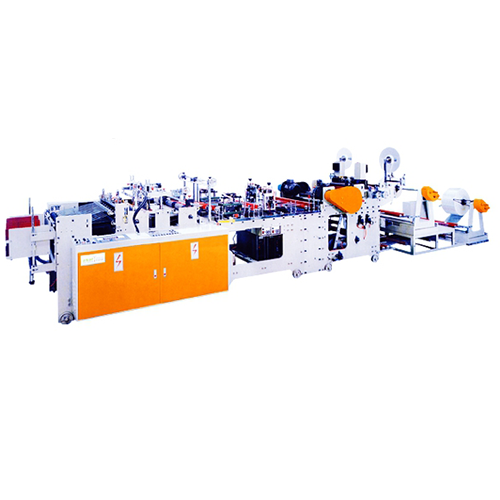

Automatic Slider Taper Bag Making Machine

Categories : Plastic Bag Making Machines

- Suitable for LDPE, PP OPP CPP BOPP and EVA. - The unit begins from triangular folding unit with EPC, Tension control unit with automatic - calculation, zipper attachment, automatic slider inserter, gang puncher, ultrasonic stamping, precise triangular sealing, automatic scrape remove system, collector to wicketer windmill fully automatic in one process. - Servo Driven is fast and precise. - Servo motor cutting Control System. - The unit uses PLC Control System.

Hydro Dipping Machine - Semi-Automatic - YHT223AXF

Categories : Hydro Dipping Spraying Equipment

Dipping Tank + Auto Film Layer + Auto Spray System Dipping Tank 3 meters length. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. YHT-223A2XF This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. This system can memorize multiple sets of different processes. YHT-223A2XF is perfect for large product and medium quantities of production/day

Floor Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

The separated design of a blower and a suction hopper with mighty horsepower is suitable for long distance conveying. The flexible combination of one blower with one suction hopper up to four suction hoppers can help you to save space and equipment investment cost. That also keeps your resin away the pollution and extend suction points easily for future need. TA series Easy use by a quiet and powerful induction motor. The motor cabinet can be placed on the floor for convenient operation and the suction hopper on the hopper dryer for easy installation. TB series Use the same commutator motor as the BC series, and separate motor cabinet and suction hopper design as the TA and TC series. Combine the advantages of the hopper mounted and floor mounted loaders. TC series The blowers are belt-driven that are the best choice for silent operation. Patented Optional Parts Vortex Cyclone (VC): Works with any auto loaders to stop the regrinded resin from discharging to the surrounding area. Filter Set: s optional equipment from YANN BANG is perfect for dust-free of indoor working place. To do the filter routine maintenance is so easy without dirtying your hands and place. Unload the filter set without opening the cover until move to the please you want to clean. Auto Dust Cleaner: Saves your time and labor. No need to clean your filter anymore. The Auto Dust Cleaner is designed to install upon the filter of the loader. Set the timer and it cleans your filter routinely.

2-in-1 Conveying Dryer (CD)

Categories : Dryers and Dehumidifiers For Plastic Materials

Hopper dryer combine vacuum loader is perfect to move anywhere for your need. A stainless insulated hopper dryer with dual layer to help drying better and faster. Save more energy and increase higher efficiency. A vacuum loader automatically supplies dried resin to avoid the shortage of material during production. Installed pipe-clean device (Taiwan Pat:M299801) and closed-loop can prevent the moisture return, static electricity and resin pollution inside the pipe for better quality. Patented Heat-recycler (Taiwan Pat:226245;China Pat:01258213.1) can save your energy, increase drying and decrease the pollution of hot air and dust. Installed weekly timer and safety protectors can save your labor cost and protect operators in better working environment. Only one control unit is convenient for you to monitor all suction points. Able to extend suction points up to four as 1 to 4 small central conveying system to supply resin for raw material areas and numerous molding machines. Save your equipment cost and space without extra spend.

Hopper Mounted Auto Vacuum Loader

Categories : Loaders and Conveyors

BC series Use high speed, powerful, single phase commutator motor and is the smallest and the most economical loader in our range. Compact size, light weight, low noise, easy operation and installation, suit to convey one kind of resin or material, can install upon a hopper dryer or molding machine directly. It is ideal for small machines. BL series Easy use by the three phase powerful induction motor. Suitable for medium to large size machines, such as extrusion molding machine.

Twin Shaft Shredder (Kroko Twin Series)

Categories : Plastic Shredders

Intelligent control system The program system monitoring the shredding status and allows automatically reverse and forward motion to keep most stability while creating best production. High radial loads with high efficiency and great stability The professionally designed shaft and blades are made with high wear-resistant steel and processed by heat-treatment to increase the service life. It can withstand higher radial load and create higher efficiency while keep the best stability.

FP-X Turret Rewind Shrink Sleeve Seaming Machine

Categories : Shrink Sleeve Machinery

HCI's new generation of FP-X high-speed turret rewind shrink sleeve seaming machines which meets the requirement of high-speed production, automatic roll-changing and online inspection. With rewind auto splicing, In-Line layflat and Solvent Auto Detection system to have seaming & doctoring process two-in-one. Together with new developed precise needle type solvent supply system is highly increasing the stability of solvent application, forms and seals on shrink sleeve making process.

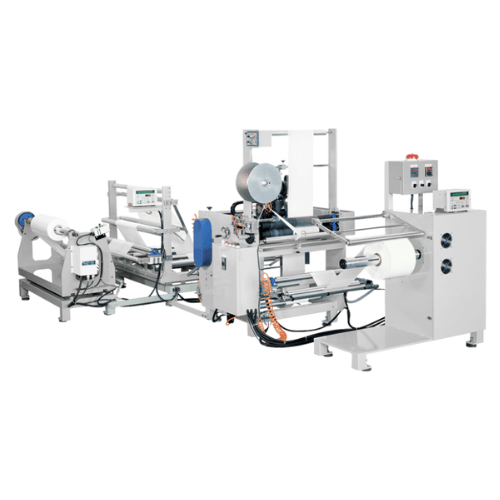

Automatic Packing Tape Slitting & Rewinding Machine

Categories : Slitters and Rewinders

Application: BOPP tape, cellophane tape, masking tape… (according to customer informed material) yicheen

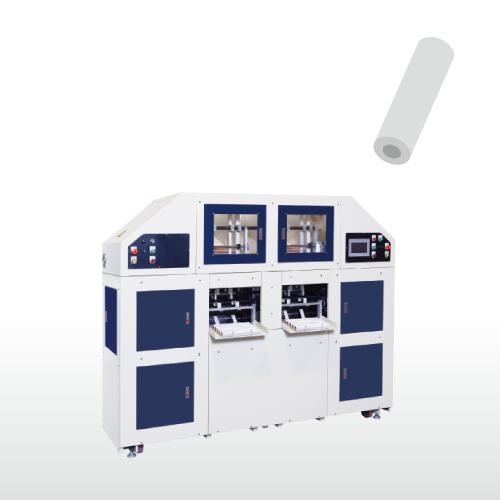

Paper Core cutter

Categories : Cutting Machines

Application:Double side adhesive tape, Paper core, PVC, Rubber, leather, foam… etc. roll tube yicheen

Fully Automatic High Speed 4 Spindles 2 Lines Stretch Film Re-Winder (Industrial Type) / SIWCR-500-L2

Categories : Slitters and Rewinders

-Computer control over the entire process -From film roll to final pruduct, one process flow -Automatically core changing system

Fully Automatic High Speed 4 Spindles 2 Lines Stretch Film Rewinder(Kitchen Type)/ SWCR-350-L2

Categories : Slitters and Rewinders

-Computer control over the entire process -From film roll to final product, one process flow -Automatically core changing system

Automatic Strand Pelletizing System

Categories : Plastic Pelletizer Machines

Born For Extreme Automation The molten polymer been extruder from the die, fall into automatic water flow. High-pressure water flow from a special designed spray nozzle pulls the strands immediately while cooling at the same time. No more drawing strands before pelletizing. Minimize the lump waste during drawing the strands. GENIUS

Economic Type Slitting Machine

Categories : Slitters and Rewinders

Application:OPP、BOPP、PET、PVC、transfer paper、foil、Non-woven cloth…etc. yicheen High speed rewind, machine speed is 1~300M/min duplex rewinder Swing out unwind and rewind air shaft. Equipped with automatic tension controller and load cell, tension value digitally display, increase tension control precision and stable. Equipped with EPC/LPC position control to ensure accurate slitting position. Equipped with razor cutter and circular shear cutter. Rewind section equip with diameter-detector to control rewind motor speed. Equipped with pneumatic press roller on re-winder to eliminate the air go into rewind film and avoid film slip. Full digitally computer control system, equipped with PLC and touch panel system ,error message alarm and indication are displayed on the screen.

High Speed Slitting Machine

Categories : Slitters and Rewinders

Application: OPP、BOPP、PET、PVC、transfer paper、foil、Non-woven cloth…etc. yicheen High speed rewind, machine speed is 1~300M/min duplex rewinder Swing out unwind and rewind air shaft. Equipped with automatic tension controller and load cell, tension value digitally display, increase tension control precision and stable. Equipped with EPC/LPC position control to ensure accurate slitting position. Equipped with razor cutter and circular shear cutter. Rewind section equip with diameter-detector to control rewind motor speed. Equipped with pneumatic press roller on re-winder to eliminate the air go into rewind film and avoid film slip. Full digitally computer control system, equipped with PLC and touch panel system ,error message alarm and indication are displayed on the screen.

Slitting Machines CLASSIC/ HSI

Categories : Slitters and Rewinders

All models slitting machine are able to slit various types and qualities of flexible packaging substrates as well as printing paper. The SLIT production line comes standard with differential rewinds and automatic tension control systems to be able to slit the toughest jobs. It is truly a one stop slitter.

Fully Automatic Hot Slitting & Sealing Machine LY-1200HS

Categories : Plastic Bag Making Machines

Introduction LY-1200HS is a fully automatic, high speed hot slitting and sealing machine which converts sheet film into tubular film with good quality of sealing at the edge of film. It is suitable for full printing film. Features Servo motor for rewinding unit. Line position control. Auto-tension control for unwinding stand. Auto-tension control for rewinding stand. Edge trimming and waste collecting unit.

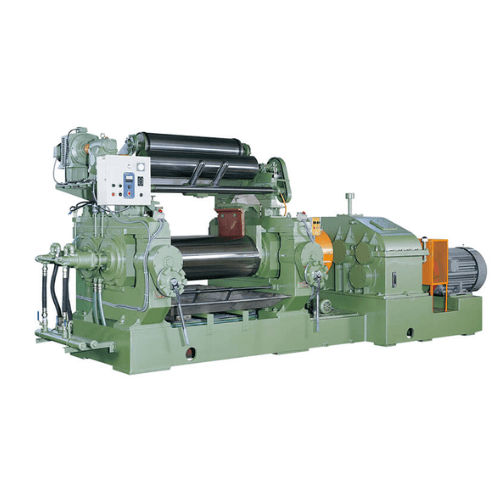

Stock Blender For Rubber & Plastic

Categories : Mixers and Blenders

TYPICAL APPLICATIONS The stock blender is installed on the two roll open mixing mill to assist the operator in the mixing of rubber material and chemical power. It features automatic continuous operation, reducing labor requirements, providing safe working conditions, lowering the material temperature, speeding the mix rate and maintaining quality. The action of travel guide holder for the stock blender includes both guide bar type and hydraulic type.

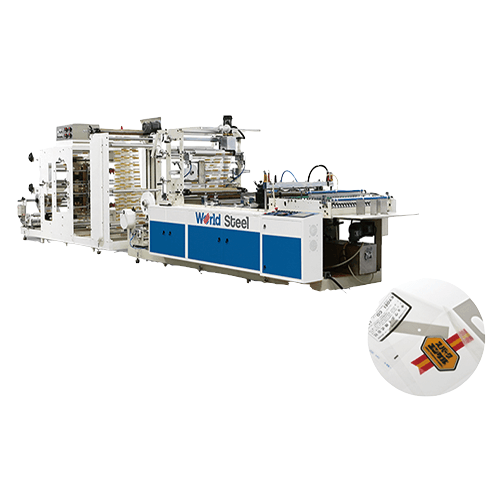

High Speed Automatic Side Sealing And Cutting Bag Making Machine

Categories : Plastic Bag Making Machines

Our high speed side automatic sealing and cutting machine is suitable for a range of shapes folds and pockets, interlinking with other equipment to be able to make even more types of bags for easy exchange. Some examples of pattern types include: punching equipment for round holes, butterfly holes, utilizes handheld punching equipment for accuracy and can produce perforations for letter and packaging tear off strips. Using a vertical up and down heat sealing system and supersonic sealing line device means improved sealing quality and can also produce anything from 'V' type standing pouches to handbags. If this isn't enough, we also can provide extra parts for improved production accuracy and quality, this includes EPC edge sensor, servo motor to drive the machinery and an automatic conveyer to get your finished products to the packing section as soon as possible. This machine is also suitable for already perforated and/or folded films.

Fully Automatic Side Sealing Machine for PP, OPP, BOPP, CPP, LDPE, HDPE LY-650S / LY-800S / LY-1000S

Categories : Plastic Bag Making Machines

LY-650S/800S/1000S series are basic high-speed side sealing machine. It equips with servo-driven feeding system and human-machine interface for customers easy and friendly operation. It can put on many other options for customers having flexible production.

Fully Automatic Side Sealing Machine with Zipper Device LY-800SZP

Categories : Plastic Bag Making Machines

Fully Automatic Side Sealing Machine With Zipper Device LY-800SZP

Automatic High-Speed Three Side Sealing Bag Making Machine

Categories : Plastic Bag Making Machines

AUTOMATIC HIGH-SPEED THREE SIDE SEALING BAG MAKING MACHINE

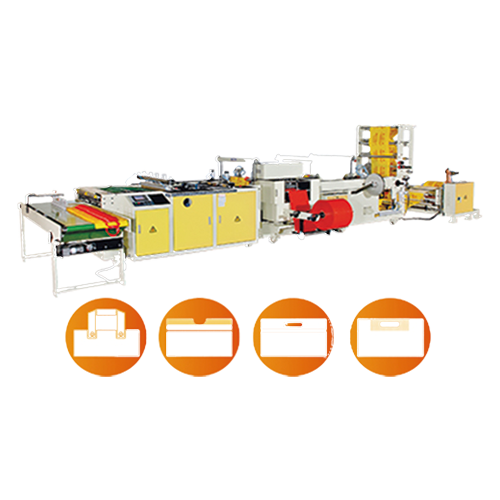

4 In One Side Sealing Bag Making Machine with Servo Motor Control Model: CW-PFM-SV

Categories : Plastic Bag Making Machines

Full Automatic Side Sealing Soft Loop Handle, Draw Tape, Die Cut & Patch Handle Bag Making Machine by Servo Motor Control.

Zipper Applicator and High Speed Side Sealing Machine

Categories : Plastic Bag Making Machines

Zipper Applicator and High Speed Side Sealing Machine The machine uses fully automatic digitalized servo motor to control length; it is easy for operation and provides strong sealing and quality appearance.

APS Automatic Bag Packaging Side Sealing Machine

Categories : Plastic Bag Making Machines

Automatic Bag Packaging Side Sealing Machine

Semi-Automatic Patch Handle Making Machine/Semi-Automatic Soft Loop Handle Making Machine

Categories : Plastic Bag Making Machines

Converting Shopping Bag Semi-Automatic Patch Handle Making Machine/ Semi-Automatic Soft Loop Handle Making Machine SEMI-AUTOMATIC PATCH HANDLE MAKING MACHINE/SEMI-AUTOMATIC SOFT LOOP HANDLE MAKING MACHINE

Fully Automatic Multi-Function Shopping Bag Making Machine

Categories : Plastic Bag Making Machines

Converting Shopping Bag Fully Automatic Multi-Function Shopping Bag Making Machine FULLY AUTOMATIC MULTI-FUNCTION SHOPPING BAG MAKING MACHINE

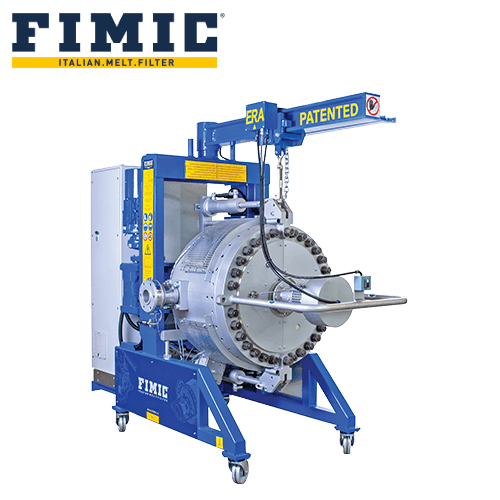

Automatic DOUBLE FILTER- ERA

Categories : Material Processing Machines

ERA is made of two internal filtration chambers and two independent discharge valves, thus enabling to setup a pre-filtration on the first step and a finer one in the second, all in the same machine! This means, in short, the possibility of using cheap punched screens (400-2000 micron) to protect the expensive laser screens (100-300 micron) coming afterwards. The resulting cost reduction is undeniable, both on the financial and energetic side. FIMIC screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

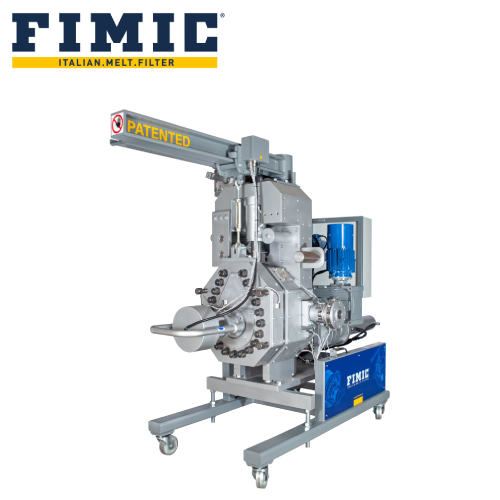

EXCLUSIVE MELT FILTER- GEM

Categories : Plastic Pelletizer Machines

Differently from RAS, this model reaches a greater filtering surface due to the presence of two filtering meshes towards which all the melt is directed, alongside two scrapers and independent discharge valves. The two blades scrape the contamination the filter collects, while the blade holder rakes it in to automatically eject it through the valve. The pressure mode can be set from the touch screen, while the blade holder rotating speed is adjustable and the valve only opens on a full cycle. In the event of a higher degree of contamination, a continuous mode is available to let the blade holder scrape continuously. In this case, a temporizer will tell the valve when to discharge. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Automatic self-cleaning screen changer - RAS

Categories : Plastic Waste Recycling Machines

Any contamination the filter collects is scraped from its surface by two blades, and then gathered by the blade-holder. Finally, anything harvested is automatically ejected through the front valve. Another important feature is the possibility to determine a pressure set-point (in pressure mode) with nothing more than a few taps on the touch screen, so that once such level is reached the blade holder (running at adjustable speed) will proceed to gather the contamination, opening the front valve only on a full cycle. In the event of a particularly contaminated input material, the filter cant be set to work in continuous mode: the blade holder will keep on scraping, while relying on temporized valve openings to discharge as needed. FIMIC- Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Automatic Melt Filter - RAS+REF

Categories : Plastic Waste Recycling Machines

The melt filter that made FIMIC technology renowned in the recycling field, enhanced with the possibility to work in backflush. RAS+REF melt filters can in fact operate in two different ways: in scraping mode or in backflush mode, providing more options to anyone wishing to process materials with mesh filters. REF therefore represents an ideal option for mesh processing with exceptional final results. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

AUTOMATIC MELT FILTER- TEN

Categories : Plastic Pelletizer Machines

TEN is FIMIC’s automatic screen changer capable of blocking even the smallest contamination particles thanks to its mesh, whose resistance allows to adapt the temperature according to the requirements and the material to be processed. The adjustable opening on the mesh output is a further guarantee of the quality of the end product. A small scraper close to the mesh harvests most waste and prevents it from breaking when it is changed. Its 1.465 cm2 filtering surface has a low load pressure; it therefore excludes any danger of degradation. It is also possible to adjust the mesh changing speed, setting a target pressure at which it will be automatically switched, to fit all the workflow to the material to be filtered. Furthermore, when changed the mesh is held by the material pressure itself and doesn’t needany other auxiliary systems. The mesh proper is available in varying filtration levels, starting from 80 micron / 170 mesh. TEN can also be adapted to finer filtration levels equipping custom made meshes. Quick opening is also always guaranteed. There’s no need for dedicated tools or skills, for FIMIC provides a pneumatic screwdriver at the time of purchase. FIMIC - Screen changers Filters Filter Recycle filter Recycle filters Recycling Filter

Rewinding Machine FSR-800

Categories : Slitters and Rewinders

For re-reeling operation of slit rolls with uneven edges or tension. FSR Rewinding Machine will help you to achieve high quality re-reeling, even without the use of an advanced slitting machine. Especially ideal for an automatic filling packaging machine which requires a large reel diameter and rigorous tension quality.

Inspection / Rewinding Machine Reversible Type( WDI Series)

Categories : Slitters and Rewinders

Worldly WDI series machine has rewinding & inspection functions. Unwinding section with EPC/LPC device control and shaft-less design. This model of machine has re-reel function can install with auto100% defect inspection device. The machine can automatic re-reel and stop to the check point when detected such as miss print, hair line or bugs & fly. It allows to secure all your finished products quality.

Automatic Batch Weighing and Mixing System

Categories : Dosing and Measuring Equipment

Automatically measuring equipment for efficient mix and material processing. Equip with auto conveying system, batching system, mixer, kneader, extruder and steel construction plant. Discharge feeder: scale screw feeder Automatically conveys material to extruder after mixing PC control monitoring system live network Complete installation of pulverizer series